Low Speed Wind Tunnel Testing Barlow Pdf Writer

. 187 Downloads.AbstractThe goal of wind tunnel design is to generate a uniform air flow with minimum turbulence intensity and low flow angle. The nozzle is the main component of wind tunnels to create a uniform flow with minimal turbulence. Pressure distribution along nozzle walls directly affects the boundary layer thickness, pressure losses and non-uniformity of flow velocity through the test section. Although reduction of flow turbulences and non-uniformity through the test section can be carried out by nozzles with high contraction ratio, it increases the construction cost of the wind tunnel.

For decreasing the construction cost of nozzle with constant test section size and mass flow rate, the contraction ratio and length of nozzle should be decreased; that causes the non-uniformity of outlet velocity to increase. In this study, first, three types of nozzle are numerically investigated to compare their performance.

Then, Sargison nozzle with contraction ratio of 12.25 and length of 7 m is scaled down to decrease its weight and construction cost. Having scaled and changed to a nozzle with contraction ratio of 9 and length of 5 m, its numerical solution reveals that the non-uniformity of outlet velocity increases by 21%. By using the Ballspine inverse design method, the pressure distribution of the original Sargison nozzle is first scaled and set as the target pressure of the scaled down nozzle and geometry correction is done. How to install language pack motorola v3 driver.

Having reached the target nozzle, numerical solution of flow inside the optimized nozzle shows that the non-uniformity just increases by 5% in comparison with the original Sargison nozzle.

Wind tunnel test results for a 2/4.5 scale MEXICO rotor Wind tunnel test results for a 2/4.5 scale MEXICO rotorCho, Taehwan; Kim, Cheolwan2012-06-01 00:00:00This paper presents the wind tunnel test results from MEXNEXT, an IEA wind task for analyzing the measurements which have been taken in the EU project ‘MEXICO’. A 2/4.5 scaled model of ‘MEXICO’ rotor was tested in the KARI low wind tunnel with 5 × 3.75 m 2 open jet test section. The aerodynamic performance of the blade which was represented by the torque was measured in the wind speed from 0 to 30 m/s by using the torque sensor installed in the rotating axis. The rotational speed of the rotor was controlled by the electric motor to keep the prescribed blade tip speed from 50 m/s to 90 m/s. Two different surface conditions, free and forced transition conditions were used for all blade tip speeds. Transition dots with 0.18 mm height were attached at the 5% chord line on both sides of the blade surface for the forced transition condition.

The torque coefficients with respect to the wind speed coefficient for the forced transition condition show same characteristics for all blade tip speed conditions except for the stall region. But, the torque coefficient for the free transition condition gradually increases as the blade tip speed increases until the tip speed reaches 76 m/s and it has the similar value above that speed. The comparison result between the free and the forced transition conditions at the blade tip speed 76 m/s shows that the torque coefficient for the former case is 30% higher than the latter case.

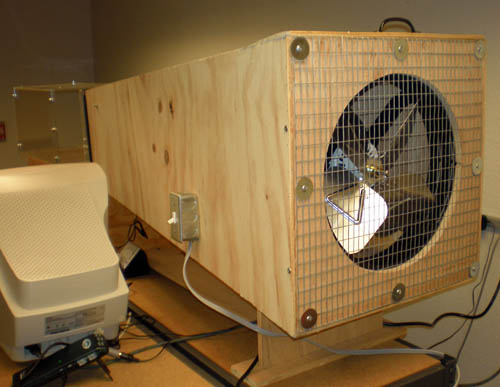

Wind Tunnel Testing Test Section

The computational results from ‘Rfoil’ and the BEMT method also shows that the aerodynamic performance of the rotor for the forced transition condition is lower than the free transition one at the wind tunnel test condition.Renewable Energy Elsevier http://www.deepdyve.com/lp/elsevier/wind-tunnel-test-results-for-a-2-4-5-scale-mexico-rotor-G4TaGYd7dM. AbstractThis paper presents the wind tunnel test results from MEXNEXT, an IEA wind task for analyzing the measurements which have been taken in the EU project ‘MEXICO’. A 2/4.5 scaled model of ‘MEXICO’ rotor was tested in the KARI low wind tunnel with 5 × 3.75 m 2 open jet test section.

The aerodynamic performance of the blade which was represented by the torque was measured in the wind speed from 0 to 30 m/s by using the torque sensor installed in the rotating axis. The rotational speed of the rotor was controlled by the electric motor to keep the prescribed blade tip speed from 50 m/s to 90 m/s. Two different surface conditions, free and forced transition conditions were used for all blade tip speeds. Transition dots with 0.18 mm height were attached at the 5% chord line on both sides of the blade surface for the forced transition condition.

The torque coefficients with respect to the wind speed coefficient for the forced transition condition show same characteristics for all blade tip speed conditions except for the stall region. But, the torque coefficient for the free transition condition gradually increases as the blade tip speed increases until the tip speed reaches 76 m/s and it has the similar value above that speed. The comparison result between the free and the forced transition conditions at the blade tip speed 76 m/s shows that the torque coefficient for the former case is 30% higher than the latter case. The computational results from ‘Rfoil’ and the BEMT method also shows that the aerodynamic performance of the rotor for the forced transition condition is lower than the free transition one at the wind tunnel test condition.JournalRenewable Energy– ElsevierPublished: Jun 1, 2012.

Comments are closed.